Tel: 0769-85619818/0799-7553966

E-mail: webmaster@dg-xinchang.com

Advantage |

Techinical Support

How to improve the service life of diamond wire drawing die Diamond wire drawing die is an important tool for the production of stainless steel wire and cable industry, especially in the field of fine wire and microwires. However, because its price is very expensive and the production cost is high, how to effectively improve the service life of diamond wire drawing die is a major issue in the wire production industry.

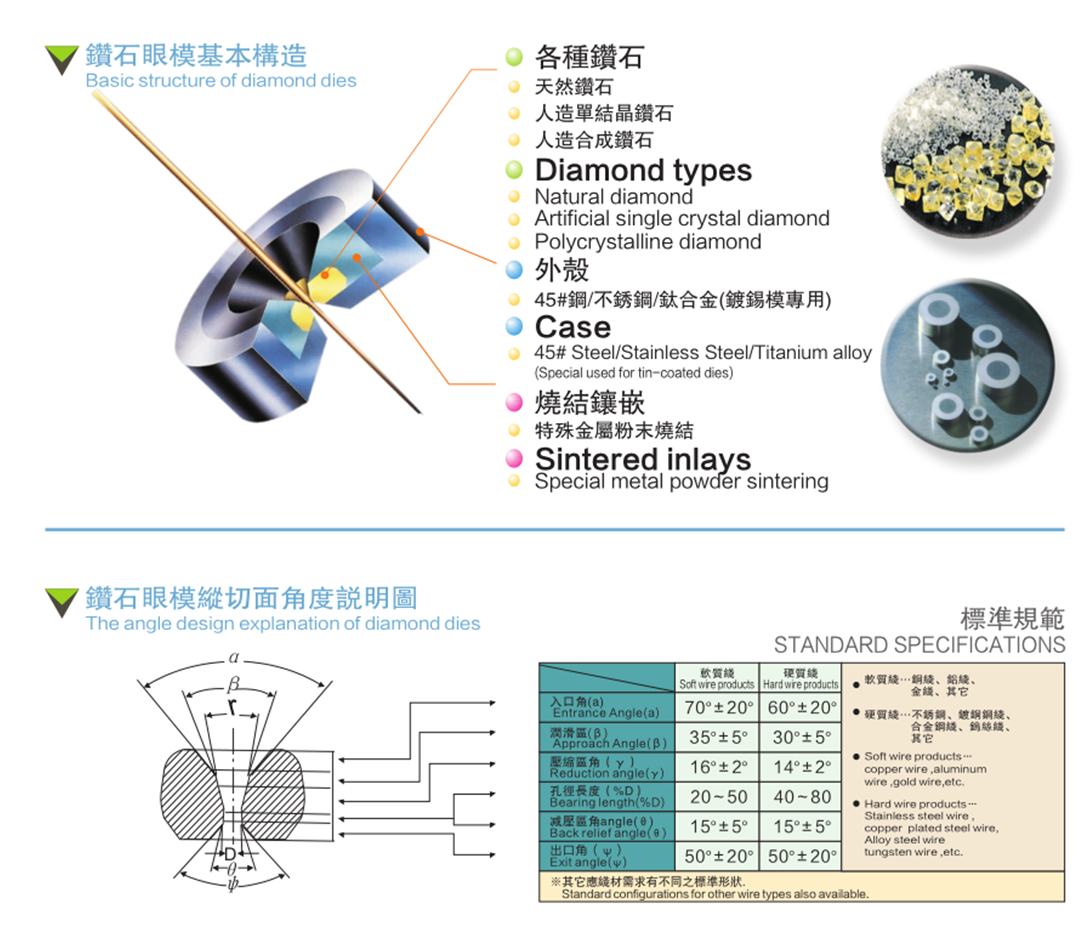

1 Introduction of diamond wire drawing die

There are two kinds of diamond wire drawing die, one is natural diamond die, natural diamond has the characteristics of high hardness and good wear resistance, the surface finish of the drawn wire is very high, because natural diamond has anisotropy in the structure, resulting in its hardness is also anisotropy, so that the wear of the die hole is not uniform, the product is not round, coupled with expensive and rare, Generally used as a fine wire drawing die or finished wire drawing die with high surface quality requirements; The other is the artificial polycrystalline diamond mold, which is an astatic polycrystalline diamond. It has the advantages of high hardness, good wear resistance and strong impact resistance. There is no anisotropy in the hardness, uniform wear, long service life of the mold, suitable for high-speed drawing. Due to the quality problems such as coarse grain size and poor polishing performance of domestic polycrystalline die, domestic manufacturers use polycrystalline die as transition die, but not as finished die. However, with the improvement of the intrinsic quality and processing level of polycrystalline mold, there is a trend to replace expensive natural diamond as a finished mold.

2 Analysis of wear causes of diamond wire drawing die

2.1 Die wear is caused by the processing quality of the drawing die itself

(1) The diamond blank and the die steel sleeve are inlaid asymmetrical, and the sintered hard alloy steel sleeve is not evenly distributed or has gaps, which can easily lead to U-shaped cracks in the process of drawing the wire;

(2) In the process of laser drilling, the sintering traces are not clean or the heat is not uniform, which will cause the metal catalyst, binder, etc. in the diamond layer to gather into a pile, which is easy to lead to pits in the mold during the wire drawing process;

(3) The mold pass design is unreasonable, the opening of the inlet lubrication area is too small, and the shaping area is too long, which will lead to poor lubrication, resulting in mold wear and even fragmentation.

2.2 Die wear caused by improper use of factors in the drawing process

(1) The shrinkage of the drawing surface is too large, resulting in cracks or breakage of the mold. Cracks or broken cracks are mostly caused by internal stress release. In any material structure, the existence of internal stress is inevitable, the internal stress generated when drawing the wire can enhance the diamond microcrystalline structure, but when the drawing surface shrinkage is too large, can not be lubricated in time, and the temperature rise is too high, it will lead to the diamond mold to show that part of the material is removed, and the stress on the microcrystalline structure is greatly increased, making it easier to crack or break.

(2) The tensile axis of the wire and the center line of the die hole are asymmetrical, resulting in uneven stress effects on the wire and wire die, and the impact of mechanical vibration will also cause high stress peaks on the wire and wire die, both of which will accelerate the wear of the die.

(3) Factors such as uneven wire hardness caused by uneven annealing are easy to cause premature fatigue damage to the diamond wire drawing die, forming a ring groove and aggravating die hole wear.

(4) The surface of the wire is rough, and the surface adheres to the oxide layer, sand or other impurities, which will make the mold wear too fast. When the wire passes through the die hole, the hard, brittle oxide layer and other adhesive impurities will cause the die hole to wear and bruise the surface of the wire quickly like an abrasive.

(5) Poor lubrication or lubricating oil containing metal debris impurities lead to mold wear. Poor lubrication will cause the surface temperature of the diamond die hole to rise too fast during wire drawing, and the diamond grain will fall off, resulting in mold damage. When the lubricating oil is not clean, especially when it contains metal debris that falls off during drawing, it is very easy to scratch the surface of the mold and wire.

3 Methods to effectively improve the service life of diamond wire drawing die

3.1 Try to use advanced mold processing technology to produce high-quality diamond wire drawing die

At present, the grinding process of foreign wire drawing die generally uses high-speed mechanical grinding machine and metal grinding needle with gold-plated corundum surface. The equipment runs smoothly, and the specifications and standardization of the grinding needle make the product more accurate. The pass size of the mold is measured by the profile recorder and the aperture measuring instrument, and the surface finish is checked by the microscope used to check the drawing die. Many domestic manufacturers are still using backward equipment, using manual operation to grind the pass, therefore, there are the following problems: pass parameters fluctuate greatly, it is difficult to process a straight cone; It is easy to grind out the transition Angle at the junction between the sizing zone and the working zone, which causes the wire to produce secondary compression in the sizing zone, increases the external friction force, shortens the length of the sizing zone and shortens the service life of the die. The frequency of needle repair varies from person to person, and the use is not standardized, resulting in poor consistency of the pass. Detection means are also backward, can only rely on visual inspection or magnifying glass, microscope and other simple tools detection, and pay attention to the mold surface finish, can not effectively detect the size of the pass, let alone control.

3.2 Select a diamond wire drawing die with good pass design

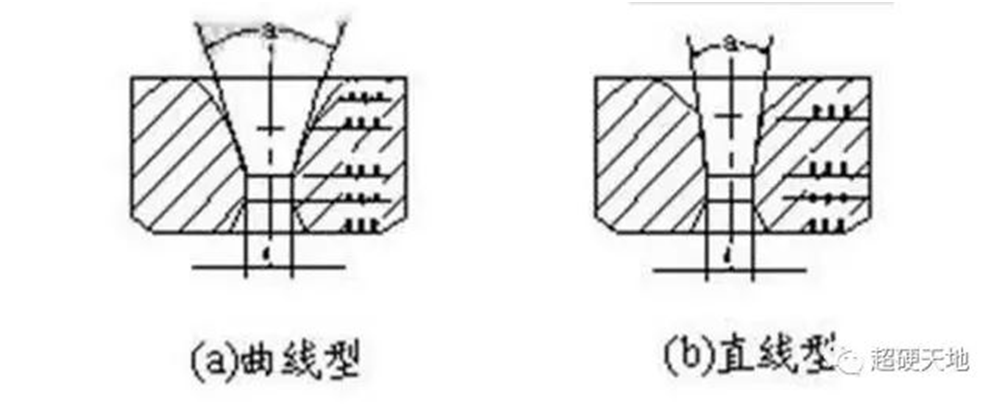

The pass of the wire drawing die is generally divided into curves (that is, R-type series) and straight lines (that is, cone series). As shown in the picture:

From the Angle of uniform deformation of the wire in the drawing die, it seems that the curve type is better than the straight line. This pass type is designed under the guidance of the theory of "smooth transition", and its pass structure can be divided into five parts according to the nature of work: "population area", "lubrication area", "work area", "diameter area" and "sun zone". The junction of each part requires "chamfering" and smooth transition. The mold of grinding the entire pass into a large, solitary surface with different curvations was still suitable for the conditions of drawing speed at the time. By the end of the 1970s to the early 1980s, with the improvement of the wire speed, the service life of the wire die became a prominent problem. In order to adapt to the requirements of high-speed cable pulling, T.Axwall and E.G. ennth of the United States proposed the "linear" theory. The theory focuses on the lubrication and wear factors in the drawing process, and points out that the improved rectilinear drawing die pass should have the following characteristics:

(1) The longitudinal profile line of each part of the pass must be flat and straight, and the drawing force of the flat working cone is minimum;

(2) The connecting part of each part must be obvious, so that each part can give full play to their respective roles and avoid the transition Angle reducing the actual length of the sizing area;

(3) Extend the height of the entrance area and the working area, so that the wire enters the middle section of the working cone of the die hole, and establish the "wedge effect" by using the wedge area formed by the entrance cone Angle and the upper half of the working cone Angle to form a more dense and firm lubricating film on the surface of the wire, reduce wear, and be suitable for high-speed drawing;

(4) The sizing area must be straight and reasonable in length. The sizing area is too long, the drawing friction increases, the wire is easy to cause shrinkage or wire break after pulling out the die hole, the sizing area is too short, it is difficult to obtain a stable shape, accurate size and good surface quality of the wire, and the die hole will soon wear out.

Through practical application, the service life of the drawing die designed by the linear theory is 3-5 times higher than that of the R-type drawing die.

3.3 The installation and use of wire drawing machine equipment should be reasonable

(1) The installation foundation of the wire drawing machine should be very stable to avoid vibration;

(2) During installation, the tensile axis of the wire should be symmetrical with the center line of the die hole through debugging, so that the stress effect of the wire and the drawing die is uniform;

(3) Avoid frequent start and stop during the line process, because the friction caused by the tensile stress at the start of drawing is much larger than the friction during normal drawing, which is bound to increase the wear of the mold.

3.4 The wire used for drawing shall be pre-treated

(1) Surface pretreatment: For the wire with dirty surface and adhering to more impurities, it should be cleaned and dried before drawing; For the wire with more oxide skin on the surface, it should be acid fine and dried before drawing; For the wire with peeling, pitting, heavy skin and other phenomena on the surface, it should also be polished by the polishing machine and then pulled;

(2) Heat treatment: For wires with excessive hardness or uneven hardness, the hardness should be reduced by annealing or tempering first, and the wire should maintain good hardness uniformity before drawing.

3.5 Maintain appropriate drawing surface shrinkage

Diamond wire drawing die itself has the characteristics of hard and brittle, if used for large shrinkage drawing, it is easy to lead to the mold can withstand the stress and fracture scrap, so according to the different mechanical properties of the wire, choose the appropriate shrinkage for drawing. Drawing stainless steel wire with diamond mold, the general single-pass surface shrinkage does not exceed 20%.

3.6 Use lubricants with good lubricating properties

In the drawing process, the quality of the lubricant and the supply of lubricant are sufficient to affect the service life of the drawing die. Therefore, the lubricant is required to have a stable oil base, good oxidation resistance, excellent lubrication, cooling and cleaning properties, and always maintain the best lubrication state during the entire production process, in order to form a film that can withstand high pressure without being destroyed, reduce the friction in the working area, and improve the service life of the mold.

During use, it is necessary to constantly observe the condition of lubricating oil, if it is found that there is serious discoloration or an increase in metal powder in lubricating oil, it is necessary to replace or filter in time to avoid the lubricating oil due to oxidation and lubrication performance reduction, and avoid the fine metal particles falling off during the drawing process to damage the mold.

3.7 Regular maintenance and grinding of diamond wire drawing die

In the long-term use of the die, the die wall is subjected to strong friction and erosion of the metal wire, which will inevitably produce wear phenomenon, the most common is the annular groove (dent) at the entrance of the working area wire. The appearance of the ring groove of the drawing die aggravates the wear of the die hole, because the small particles of the core material that are loose on the ring groove are brought into the working area and the caliper area of the die hole by the metal wire, which acts as an abrasive, and the wire that enters the die hole aggravates the wear of the die hole like a grinding needle. If it is not replaced in time to repair, then the ring groove will continue to accelerate the expansion, making the repair more difficult, and even cracks may appear in the deeper part of the ring groove, so that the mold is completely broken and scrapped.

From experience, it is very economical to develop a set of standard standards, strengthen daily maintenance, and often overhaul the mold. Once the mold has any slight wear, timely polishing, the time taken to restore the mold to the original polishing state is shorter, and the mold pass size has no significant change.

To sum up, in order to extend the service life of the drawing die, in addition to selecting the appropriate die material, designing the reasonable pass size, improving the manufacturing level of the drawing die, and making the surface finish of the die hole meet the process requirements, it is necessary to determine the reasonable pass compression rate and improve the service conditions of the drawing die. In the process of use, pay attention to the daily maintenance of the mold, should be frequently washed and changed, and ensure that the tensile process has a good lubrication effect. About the use of wire drawing die and maintenance points The use of wire drawing dies In order to ensure high quality wire materials and effectively control the cost of using the mold, the following points should be paid attention to when using the wire drawing mold 1. Ensure the smooth operation of the wire drawing equipment: the wire drawing drum wheel, the line guide wheel should be smooth, flexible, and strictly control its runout tolerance. If the drum and guide wheel are found to be worn, they should be repaired in time. 2. Good lubrication conditions are an important condition to ensure the surface quality of the wire and extend the life of the mold, often check the lubrication indicators, remove the copper powder and impurities in the lubricating oil, so that it does not pollute the equipment and die holes, such as lubrication failure, must be replaced in time, clean the lubrication system. 3. Reasonable mold allocation ensures the surface quality of the wire, the control size is accurate and consistent, reduces the wear of the wire drawing drum, and reduces the operating load of the equipment. For sliding wire drawing machine, it is the first step to be familiar with the mechanical elongation of the equipment and choose the sliding coefficient reasonably. 4. Select the mold pass according to the material of the wire being drawn and the surface reduction rate of each wire drawing. Generally speaking, the harder the wire is drawn, the smaller the compression Angle of the mold and the longer the sizing area; And vice versa. The reduction rate of each wire drawing is also closely related to the compression Angle of the corresponding die, and the size of the compression Angle should be appropriately adjusted according to the size of the reduction rate.

Maintenance of wire drawing die: The effective maintenance and repair of the wire drawing mold is crucial to reducing costs. Due to the vibration of the wire, some slight annular wear is first produced in the area that first contacts the wire in the compression zone of the wire drawing die, and then it continues to expand until the sizing zone, resulting in a serious decline in the surface quality of the wire and an expansion of the size of the wire. Not only that, serious wear will cause the mold to produce horizontal cracks (mainly in the process of drawing soft wire) or longitudinal cracks (mainly in the process of drawing hard wire), resulting in premature mold scrap. Therefore, according to the types of drawn wire, drawing characteristics, scientific development of wire drawing die maintenance standards. Under normal circumstances, slight ring wear can be restored to use only by polishing, or slightly expanded diameter can meet the requirements of wire drawing. Excessive wear will greatly reduce the number of mold repair, or even scrap, making the cost of wire drawing increase.

|